We offer exclusively the moulding machinery for the patented Polymer Fusion Moulding (PFM) process recently developed for moulding co mingled, post consumer plastics in to composite sheeting in various thickness and size permutations comprising outer skins of variable thickness and a foamed core which can be varied in density.

PFM is also capable also of moulding small lots of product where mould cost can be minimised due to the simple structure and low pressures of this unique process.

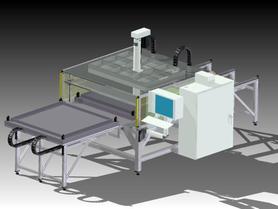

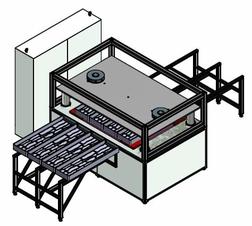

Machinery can vary therefore to provide moulded product from sizes of 300mm x 300mm to 5000mm x 2500mm with varying thickness. Four modules or more can also be combined as conceived above, into fully automated production process where annual production of more than 175,000 panels can be envisaged.

Single units , either manual operator controlled or , automated can also be offered with semi continuous operation due to the ability for one mould to be being processed whilst another is being de-moulded and refilled for the next cycle.